You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building TURBO system for YJ

- Thread starter MikeGyver

- Start date

RogueJeepr

Here!

- Location

- Utah

So, any new updates ?

I've been slowly collecting stuff to handle the tuning.

I've been too busy with school to work on it so far. I'm going to be doing some work on it this weekend and maybe get it running the full 7psi, so far it's been barely building 2-3psi because I have the wastegate adjusted mostly open so it will only barely boost.

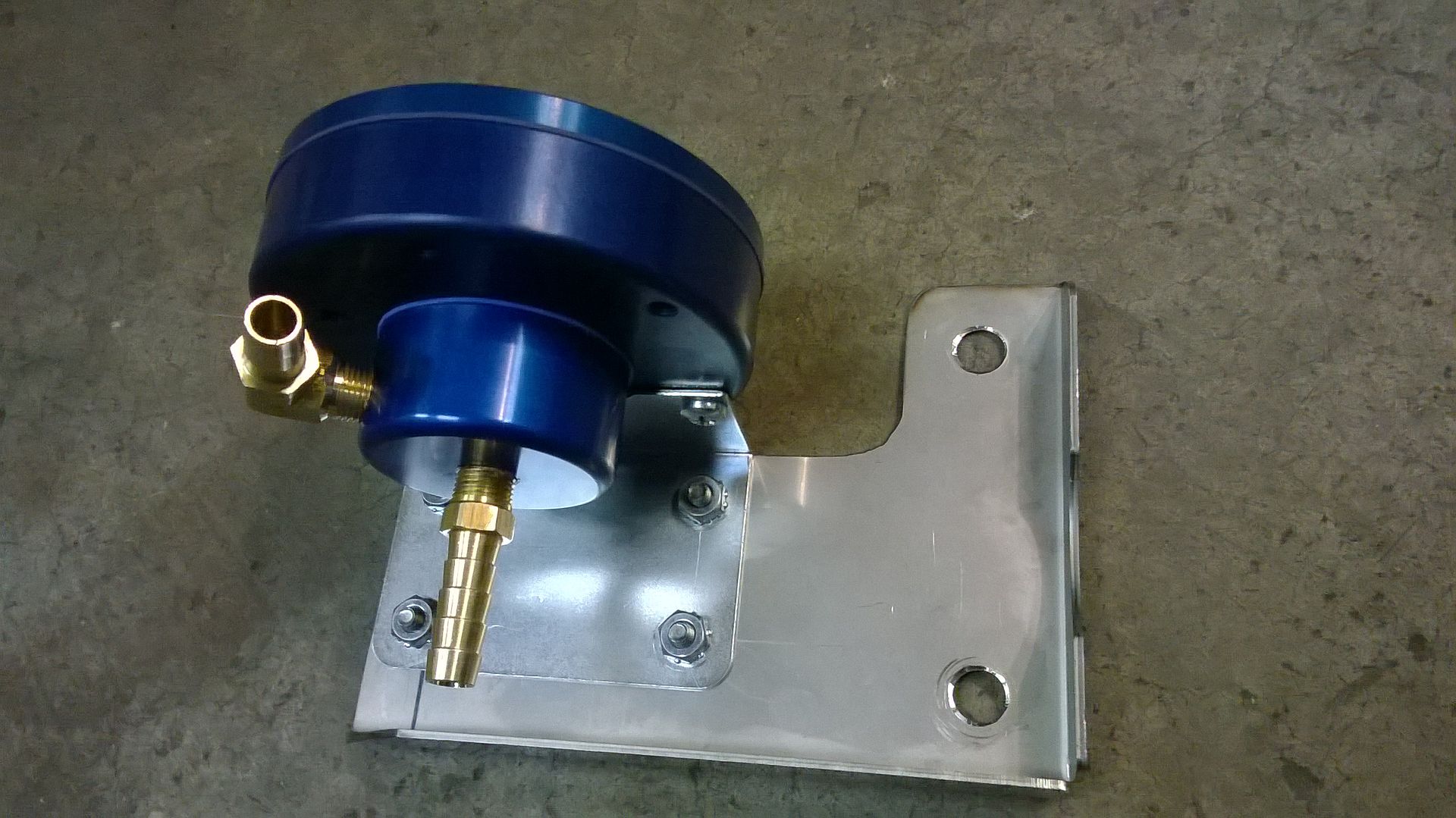

The way this system works is the fuel management unit installs in the return line (after the factory fuel pressure regulator). When it sees boost it pinches off the return line causing the rail pressure to rise. Each psi of boost will cause the rail pressure to increase by 12psi, this should allow me to use my factory 19lb/hr fuel injectors and still deliver the correct amount of fuel for the additional amount of air.

The base fuel pressure is 43.5psi (3bar) and the FMU adds 12psi fuel x 7psi boostm giving an additional 84psi, or up to ~130psi max rail pressure... hence the need for a high pressure fuel pump.

The MSD BTM ignition handles ignition timing by retarding timing a desired amount of degrees per psi of boost that it reads.

For the areas that see high pressure fuel, 1500psi 500°F Teflon, stainless braided hose safe for any automotive fluid.

I've been too busy with school to work on it so far. I'm going to be doing some work on it this weekend and maybe get it running the full 7psi, so far it's been barely building 2-3psi because I have the wastegate adjusted mostly open so it will only barely boost.

The way this system works is the fuel management unit installs in the return line (after the factory fuel pressure regulator). When it sees boost it pinches off the return line causing the rail pressure to rise. Each psi of boost will cause the rail pressure to increase by 12psi, this should allow me to use my factory 19lb/hr fuel injectors and still deliver the correct amount of fuel for the additional amount of air.

The base fuel pressure is 43.5psi (3bar) and the FMU adds 12psi fuel x 7psi boostm giving an additional 84psi, or up to ~130psi max rail pressure... hence the need for a high pressure fuel pump.

The MSD BTM ignition handles ignition timing by retarding timing a desired amount of degrees per psi of boost that it reads.

For the areas that see high pressure fuel, 1500psi 500°F Teflon, stainless braided hose safe for any automotive fluid.

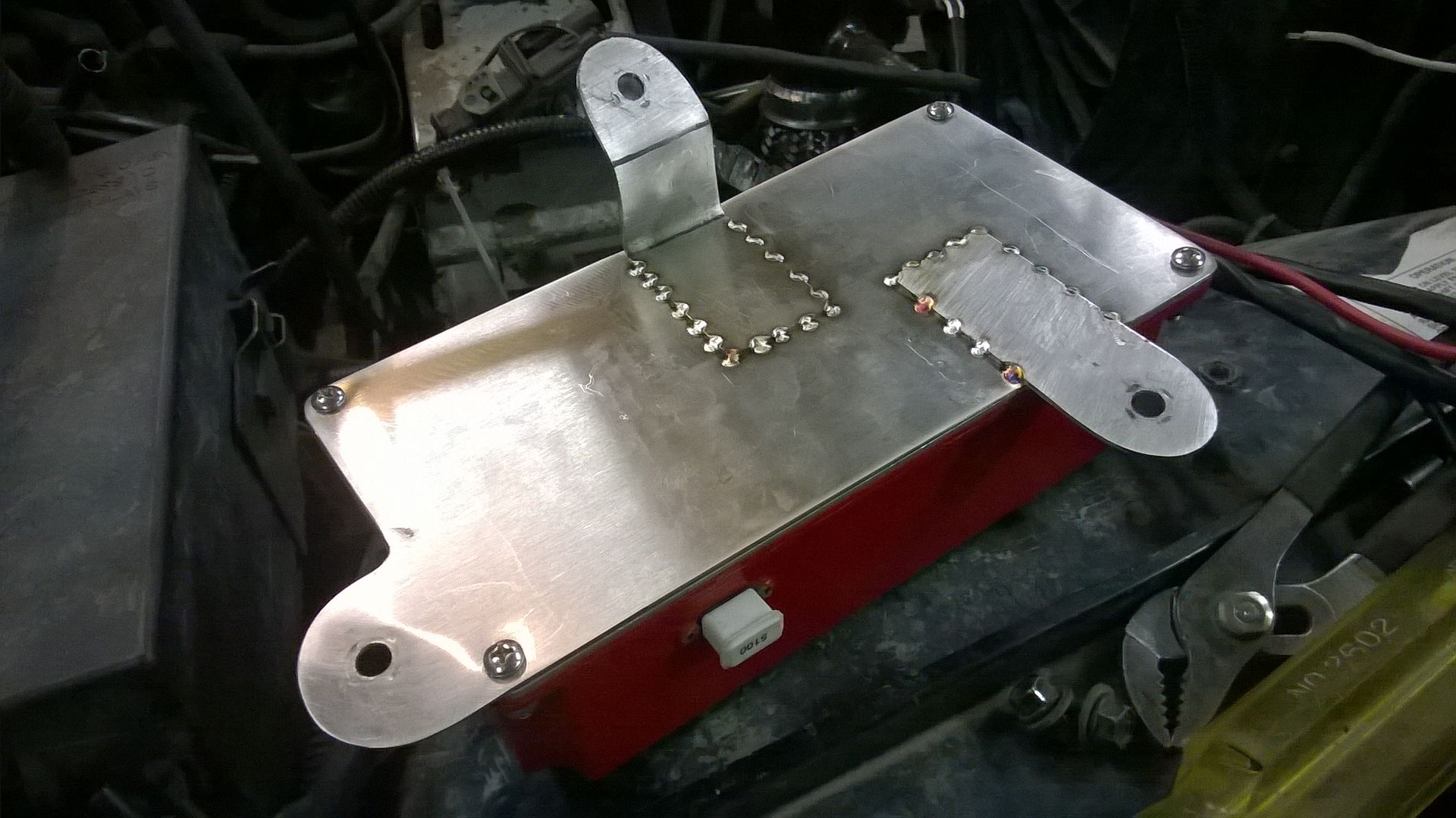

Got the MSD mounted and the NGK plugs installed.

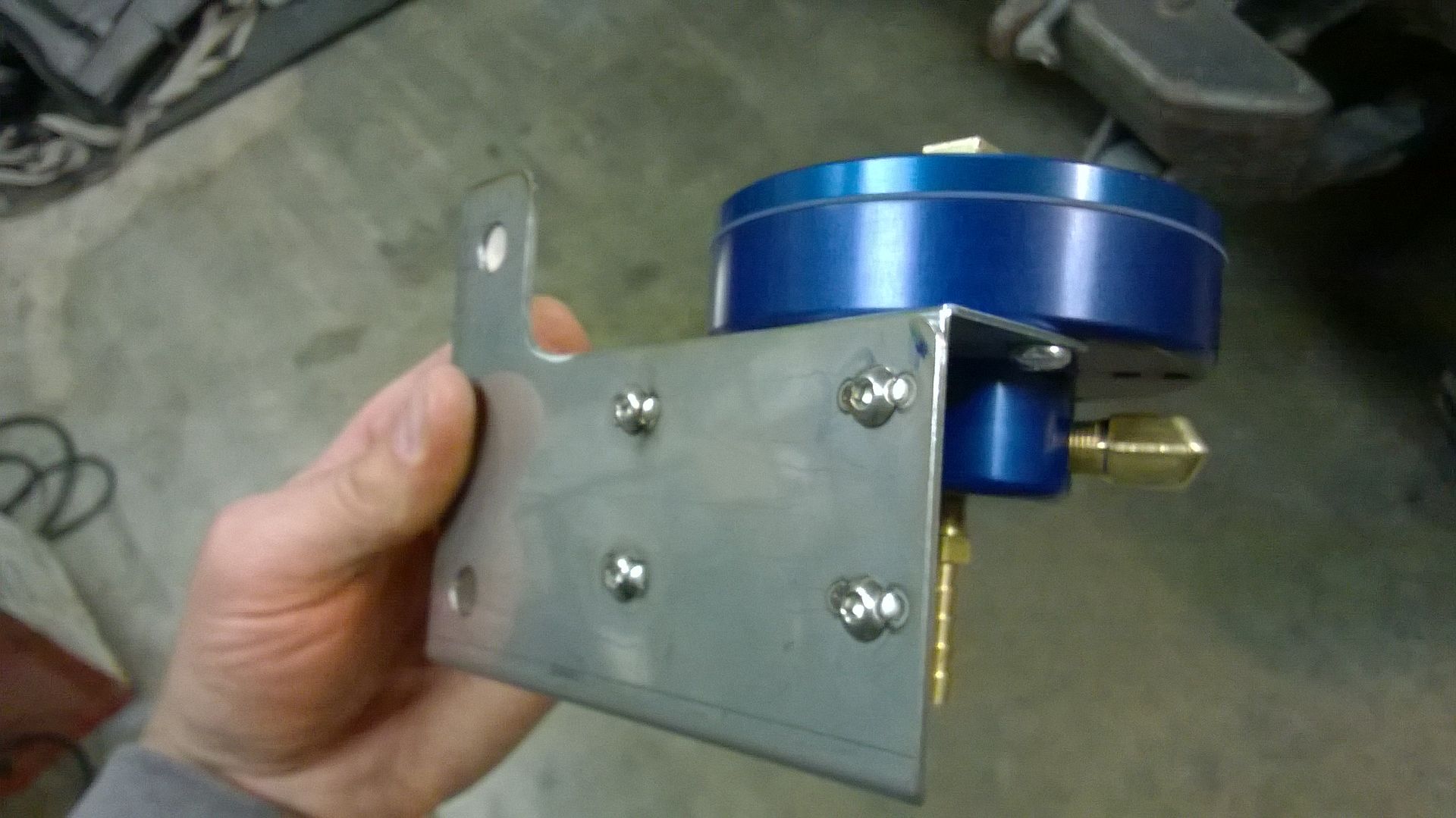

Made this mounting bracket for the FMU from some stainless scrap I had laying around.

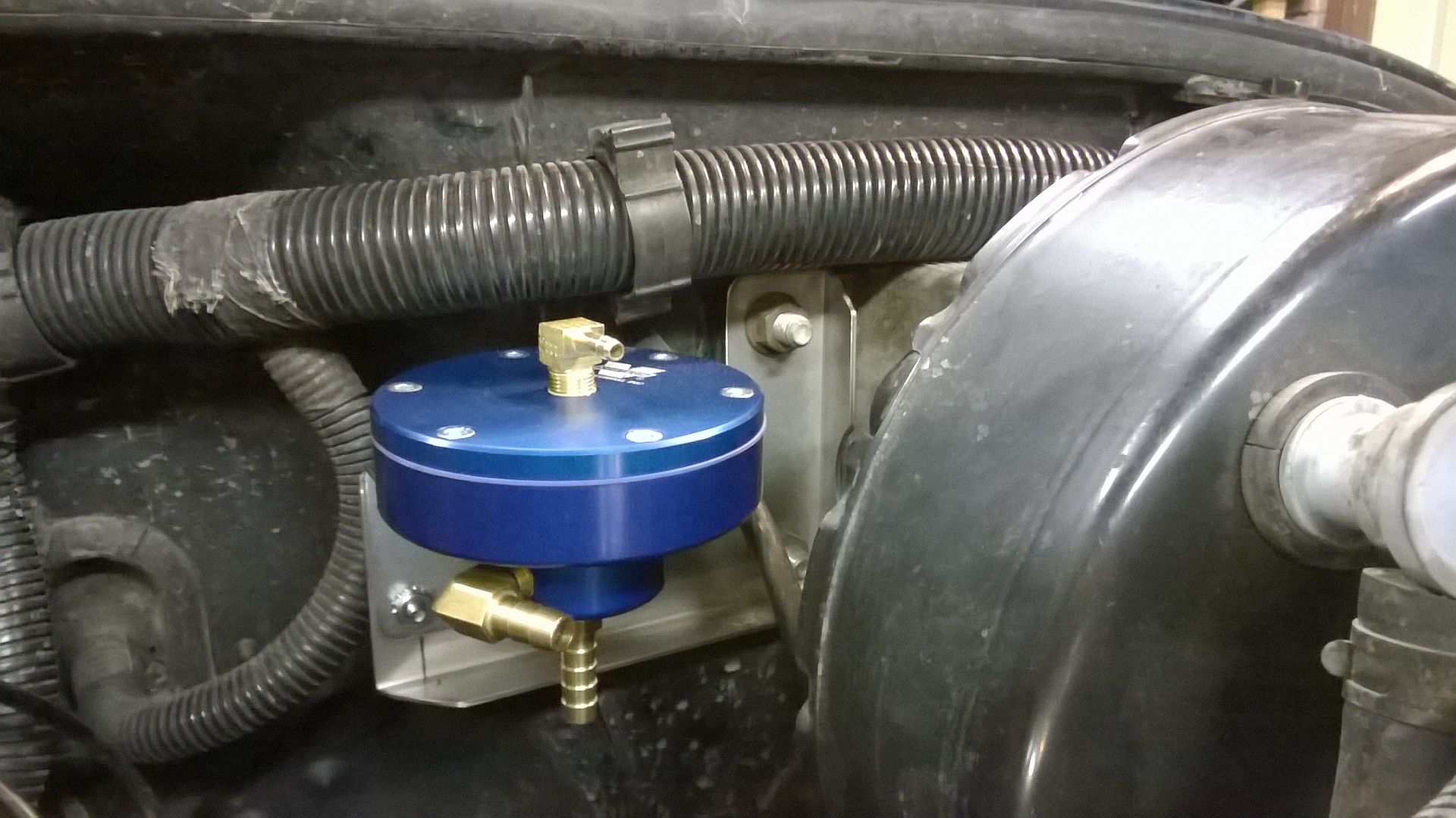

Mounted on the firewall, just inboard of the brake booster.

Tomorrow I will run the high pressure hose, and wire in the MSD ignition, and possibly drop the gas tank and install the high pressure fuel pump.

MSD boxes need to be rubber isolated. It's all over their instructions. Not using their recommended mounts, I've seen substantial losses in longevity. And almost every single MSD box I've sent in for repairs, for myself, or customers they say died because of vibration.

TurboMinivan

Still plays with cars

- Location

- Lehi, UT

The way this system works is the fuel management unit installs in the return line (after the factory fuel pressure regulator). When it sees boost it pinches off the return line causing the rail pressure to rise.

This is a tuning technique some of us used with our turbo Mopars back when nobody knew how to custom program the ECU. While raising the fuel pressure is a proven method for getting some more fuel to support more power, it was only viable for small power gains.

Each psi of boost will cause the rail pressure to increase by 12psi, this should allow me to use my factory 19lb/hr fuel injectors and still deliver the correct amount of fuel for the additional amount of air.

The base fuel pressure is 43.5psi (3bar) and the FMU adds 12psi fuel x 7psi boostm giving an additional 84psi, or up to ~130psi max rail pressure... hence the need for a high pressure fuel pump.

Our turbo cars ran 55 psi static fuel pressure, and we had a pressure-referenced regulator from the factory that gave us a 1:1 gain (meaning 10 psi of boost resulted in 65 psi of fuel pressure). In our collective experience, our injectors didn't really like dealing with much more than 75 psi of fuel pressure. Furthermore, we needed a very good fuel pump and an immaculate fuel filter to reliably maintain proper fuel flow at that rail pressure. Long story short, attempting to run triple-digit fuel rail pressure in an engine such as this sounds like a recipe for disaster.

There is a better way. Install larger fuel injectors, then install an adjustable regulator with a lower static pressure setting. Your stock injectors flow 19 lb/hr at 43 psi. Swap them out for, say, our old stock TurboII injectors which flow 32 lb/hr @ 55 psi pressure. Lower your rail pressure to ~ 27 psi and they'll only supply about 22 lb/hr of fuel, which should be within the adjustable tolerance of your stock ECU (meaning the Jeep will still idle and run well out of boost, plus pass a smog test). Now if you raise your fuel pressure to 70 psi, these injectors will flow about 36 lb/hr of fuel, which I expect should be plenty for the 7 pounds of boost you're planning to run. It will be far easier on your fuel system to maintain only 70 psi compared to your proposed ~ 130 psi, and your pump will supply a greater volume of fuel at that lower pressure, to boot.

(I have no idea if my stock injectors are compatible with your fuel rail. I used them simply as a reference for fuel flow in the above discussion.)

Lest anyone think I am talking out of my sphincter, I did this exact same thing in my drag race minivan. I removed my 32 lb/hr injectors and replaced them with 52 lb/hr units, then I installed an adjustable regulator and dropped my static pressure from 55 psi to 28 psi (which made them flow about 36 lb/hr of fuel). It ran smoothly while also allowing me to run 18 pounds of boost in daily-driver condition. (I needed more than 91 octane to go higher than that without detonation.)

$.02

- Location

- The Land Northward (Bountiful), Utah

I would agree. You're approaching the top of the duty cycle on the stock injectors.

There's a thread on pirate listing injectors that will fit the rail and their flow rates.

Don't quote me but I think neon injectors will get you close to what Dempsey is recommending.

There's a thread on pirate listing injectors that will fit the rail and their flow rates.

Don't quote me but I think neon injectors will get you close to what Dempsey is recommending.

The only thing the injector 'knows' is the pressure differential across it. If you were running a 55psi base pressure with a 1:1 regulator then 10psi boost and 65psi fuel was still the same 55psi delta pressure that's required for fueling under all moments of engine operation. You could run 200psi fuel and 145psi air on the other side and the injector wouldn't know any difference.

My setup will have a much high delta pressure which I'm hoping will still work out. I have a friend who has run stock samauri injectors around 130psi with no problems.

I've done the bigger injector and altered fuel pressure thing on a supercharged Camaro I tuned with good results but I'm hoping this will work so I don't have to buy an adjustable fuel pressure regulator, new injectors, etc. Also lowering the base pressure very much reduces atomization and drivability/mileage which is a deal breaker for this vehicle.

21lb injectors seem to be ideal, this way I only have to drop the base pressure to about 33psi (I wouldn't be interested in going any lower), and about 90psi required for 7psi boost.

also, in all of the scenarios mentioned above, injector duty cycle is the same as stock at all times.

I've never run the rubber isolators for the MSD before but its a good idea. MSD sells them for like $30 (lol...), I found them for like $5 on ebay so I'll probably buy a set.

FMU is hooked up and adding fuel for the first 2.5psi of boost or so. The stock fuel pump is only making like 75psi or something.

cut the barbed quick connect ends off the factory nylon flexible return line and reused them with the new hose from the fuel rail outlet to the FMU to the factory hard line on the frame rail

My setup will have a much high delta pressure which I'm hoping will still work out. I have a friend who has run stock samauri injectors around 130psi with no problems.

I've done the bigger injector and altered fuel pressure thing on a supercharged Camaro I tuned with good results but I'm hoping this will work so I don't have to buy an adjustable fuel pressure regulator, new injectors, etc. Also lowering the base pressure very much reduces atomization and drivability/mileage which is a deal breaker for this vehicle.

21lb injectors seem to be ideal, this way I only have to drop the base pressure to about 33psi (I wouldn't be interested in going any lower), and about 90psi required for 7psi boost.

also, in all of the scenarios mentioned above, injector duty cycle is the same as stock at all times.

I've never run the rubber isolators for the MSD before but its a good idea. MSD sells them for like $30 (lol...), I found them for like $5 on ebay so I'll probably buy a set.

FMU is hooked up and adding fuel for the first 2.5psi of boost or so. The stock fuel pump is only making like 75psi or something.

cut the barbed quick connect ends off the factory nylon flexible return line and reused them with the new hose from the fuel rail outlet to the FMU to the factory hard line on the frame rail

Last edited:

Corban_White

Well-Known Member

- Location

- Payson, AZ

I appreciate Dempsey's experience and suggestions. I also appreciate Mike's desire to do something different to try and save money by keeping as much stock as possible. So many good things in this thread! I love to learn from others experiences because it saves me money! Awesome thread!

TurboMinivan

Still plays with cars

- Location

- Lehi, UT

I have a friend who has run stock samauri injectors around 130psi with no problems.

That is amazing. Our stock Mopar injectors didn't like seeing fuel pressures that high, and their reliability suffered when we tried feeding them so much pressure.

Also lowering the base pressure very much reduces atomization and drivability/mileage which is a deal breaker for this vehicle.

Hmm, my vehicles (I did this to more than one) were always happy even with 28 psi in the rail and fat oversized injectors. As I mentioned, my fuel economy didn't drop and I still passed our tailpipe smog tests with flying colors. I can't chalk this one up to my personal luck, since there were a great many other Mopar guys doing the same thing with the same results.

Lest anyone reading along get the wrong idea, let me be perfectly clear: I really, really want this project to succeed. I may even want it more than Mike himself. I have shared some of my own experiences only in the hope that doing so might increase his chances of success. But even if he ignores every word I've said and does everything his own way, I'll still be just as happy for him when it all comes together and works well.

Nice work on the fuel line fitting, but a hose clamp? ( you had to know that was coming)

Yeah I figured he would weld a SS ring on there somehow...

Nathan

balfred

Member

- Location

- West Jordan

Any updates to this? This is an awesome build!

Sent from my Nexus 6P using Tapatalk

Sent from my Nexus 6P using Tapatalk

RogueJeepr

Here!

- Location

- Utah

Love this build. wanna see more pics, vid and hear that 2.5 chirppin a turbo !

The other day, me and a buddy went snow wheeling with tires chains up the right fork past Wallsburg.

Here's a short clip with some turboey sounds.

Yesterday I modified a spare wastegate actuator I had, it now gives a steady 6psi. I'll post more about this later.

[video=youtube;CrNkMn7IPRE]https://www.youtube.com/watch?v=CrNkMn7IPRE[/video]

Here's a short clip with some turboey sounds.

Yesterday I modified a spare wastegate actuator I had, it now gives a steady 6psi. I'll post more about this later.

[video=youtube;CrNkMn7IPRE]https://www.youtube.com/watch?v=CrNkMn7IPRE[/video]

Tonkaman

Well-Known Member

- Location

- West Jordan

Awesome

RogueJeepr

Here!

- Location

- Utah

Nice [emoji106] .

Sent from my H1611 using Tapatalk

Sent from my H1611 using Tapatalk