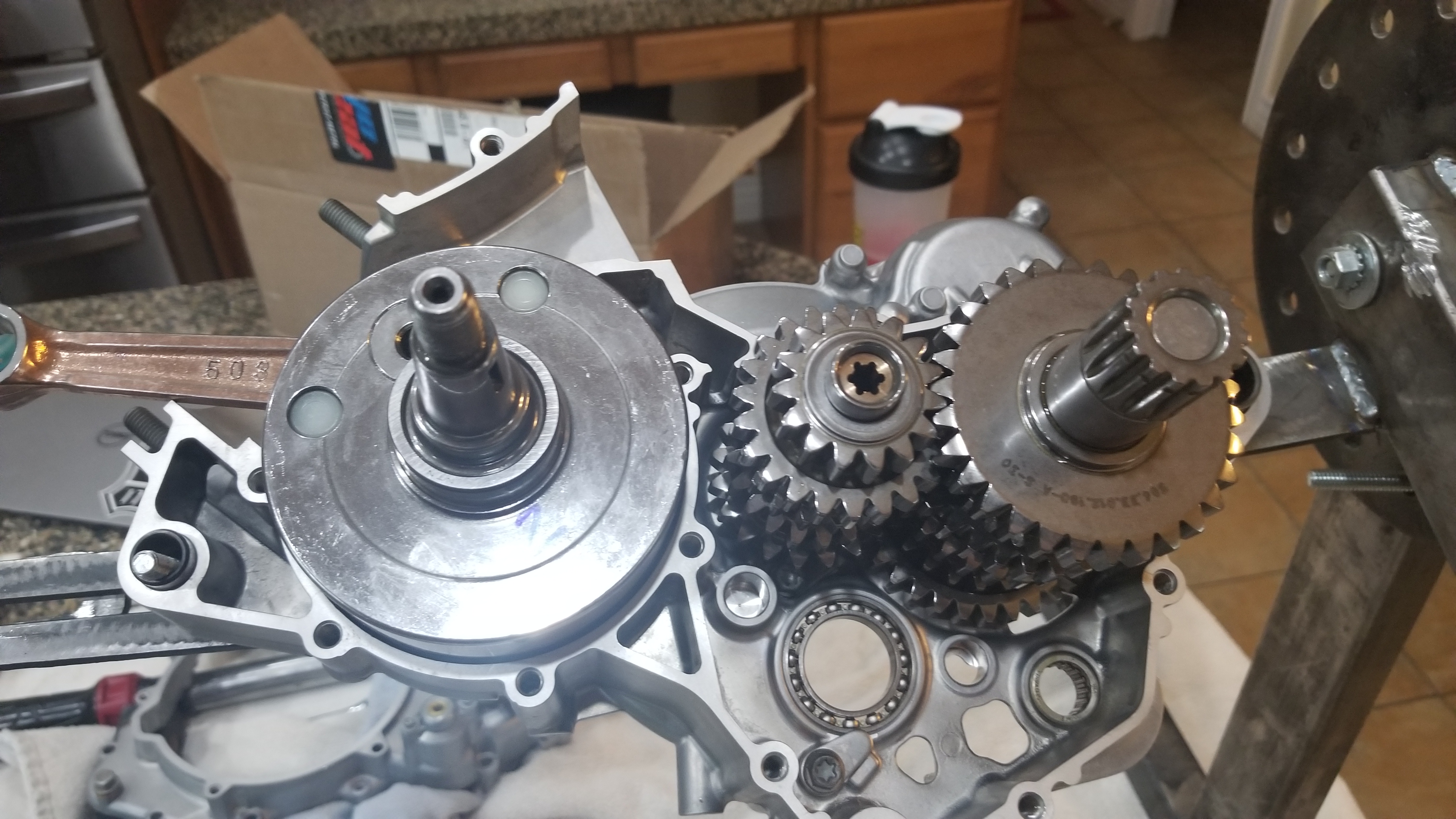

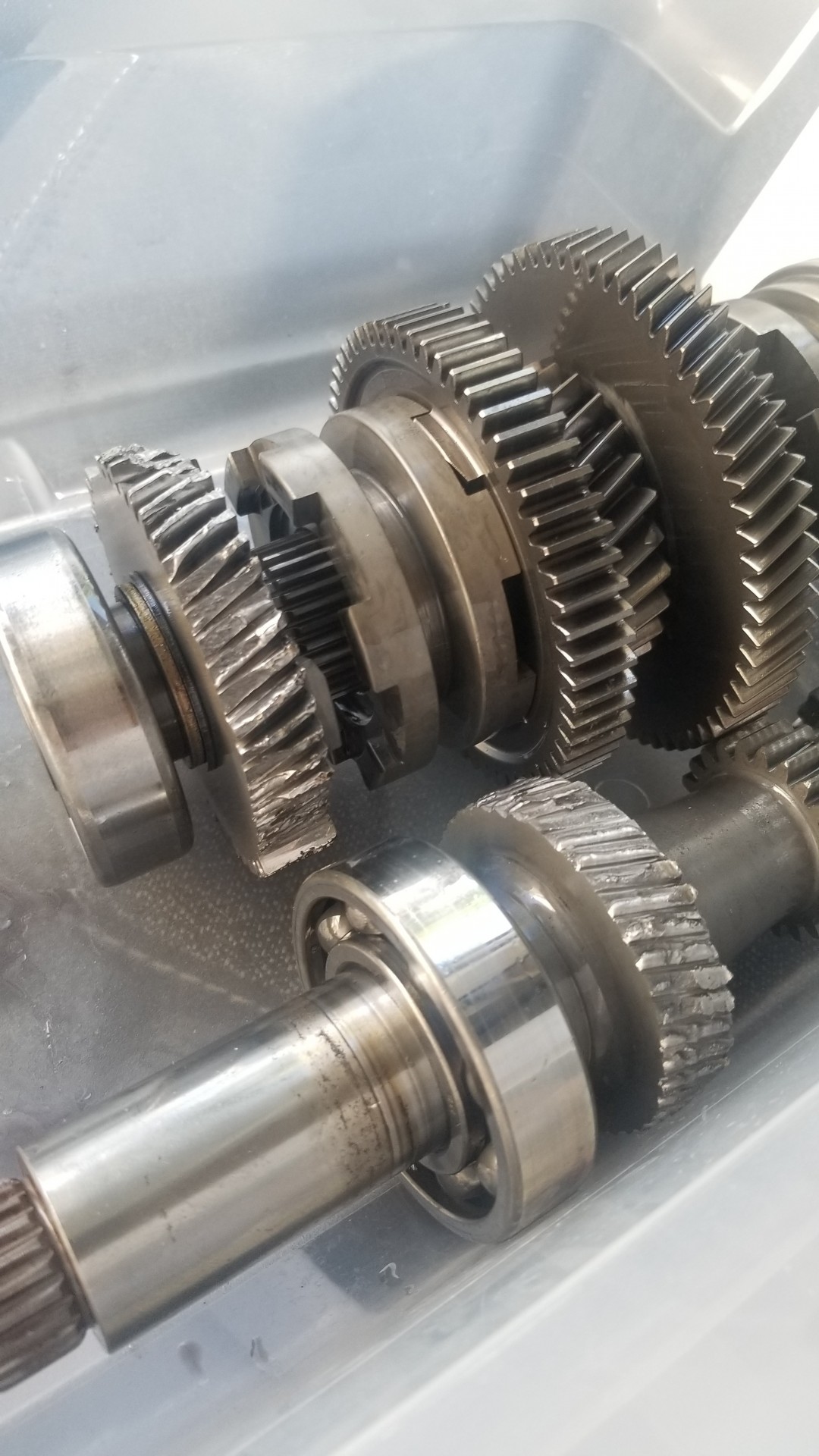

2 months since I tore this bike down to get this motor built for Loretta's.......I figured I would have the bike together and broke in by now, but as always, things move slower than planned. I am just thankful I have given myself enough time since our first regional is 3 weeks away. It took about a week longer than planned to get everything back from CryoHeat and I had a shipping nightmare with FedEx that resulted in it taking just over 2 weeks to get a box with 4 cranks in it to Texas.

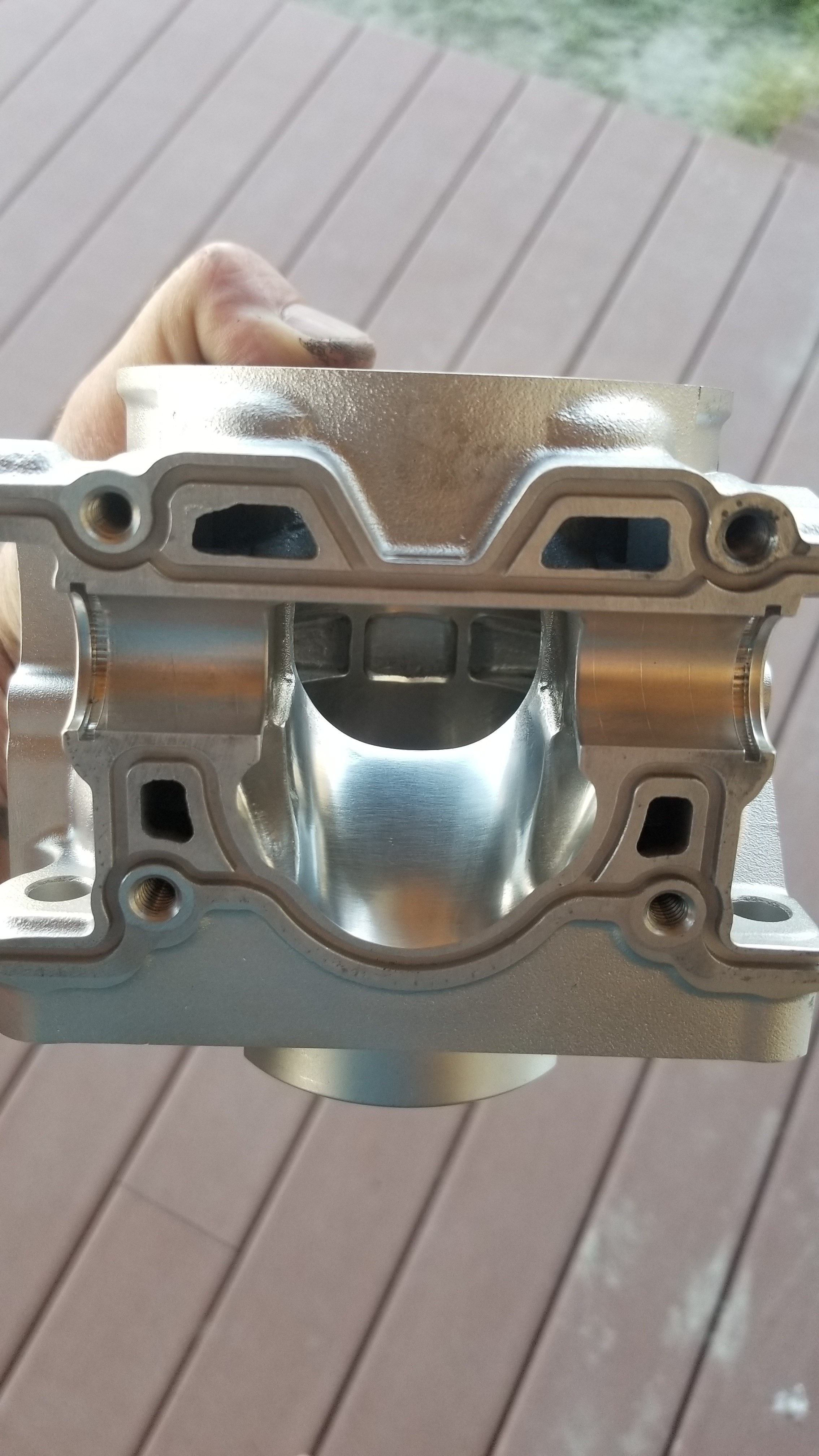

The cylinder for this bike will be back from Lynks Racing in Vermont on Tuesday of next week and my cranks should arrive from Texas at about the same time.

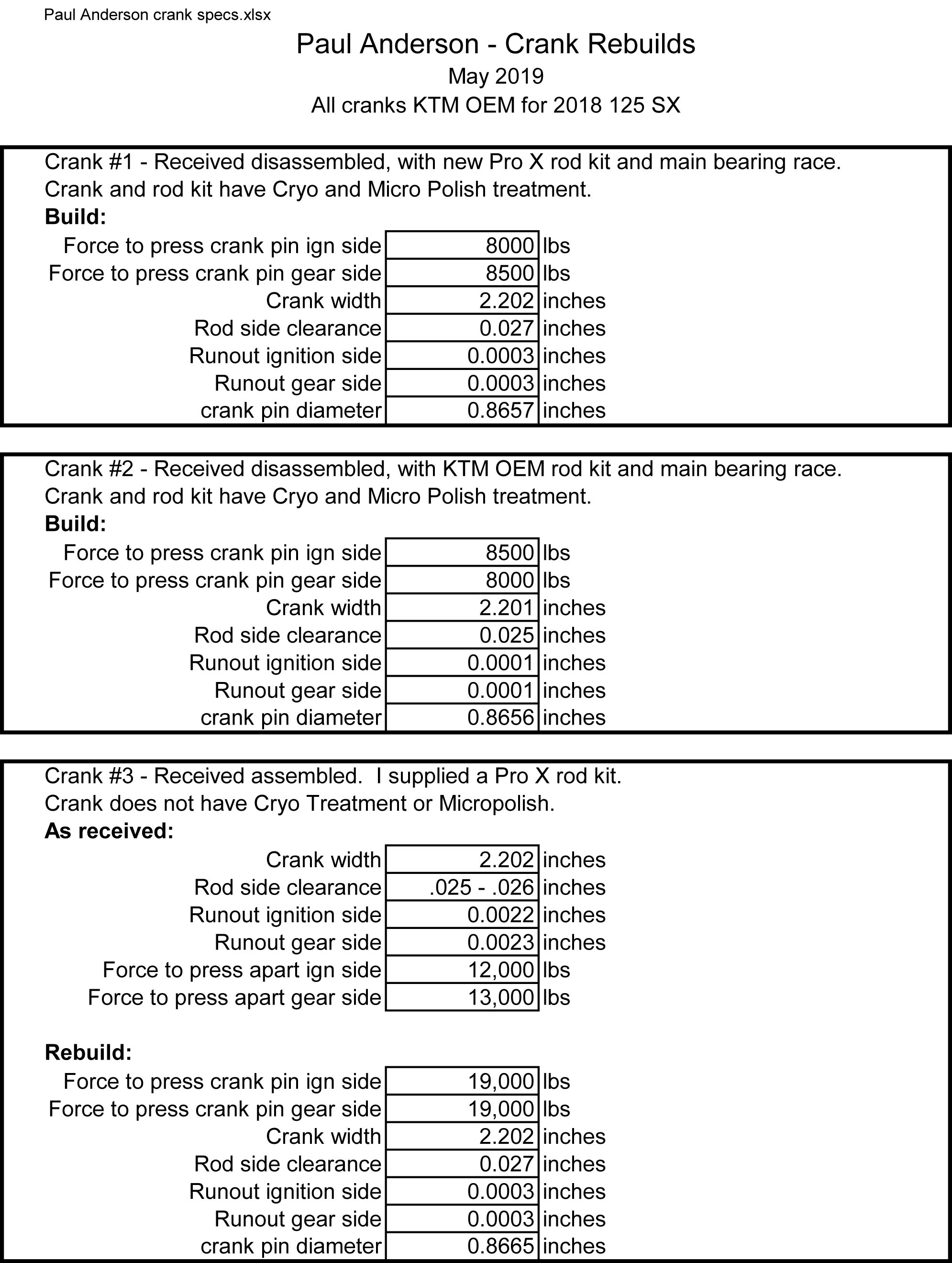

As far as the cranks go, Andrew sent me the build sheet with the runout numbers. Crank 1 & 2 on the build sheet are the CryoHeat treated and micropolished cranks, so I do not have any pre tear down numbers. Crank # 3 is a friends crank that I sent with mine to be rebuilt. His pre tear down numbers are pretty typical for a KTM crank. The rebuild run out numbers that Andrew accomplishes are pretty damn impressive. He commented to me in an email how smooth and wet the micropolished parts felt. He was surprised by the reduced force to press the pins in and so he measured them to make sure they were within a good tolerance. There is about a .0008 difference between the polished and non polished pin. Not enough to be concerned with but it took half the pressure to install it. Kind of an indication of what kind of friction reduction is achieved through this process.

Here is the build sheet for the cranks.