I haven't picked up a TIG torch for about a year now and out of the blue I got the itch again. In all, I have probably less than 10 sticks of filler through a TIG welder, so I'm still very much a rookie. I know we don't all TIG weld, but I think there is enough interest in it to make a thread for tips and tricks. Well, I have no tips or tricks to offer, but I'm willing throw some projects out there for the experienced guys to pick over so we can all learn together.

In this project I needed to make some trailer stakes with some strap pockets welded to them. The material I used was 3x1.5x1/8" rectangular tube as well as 2.5" square 1/8" tube.

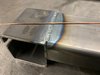

Getting my parts lined up.

These are settings I went with. The 151 seems very high to me, but maybe not. I did have my foot to the floor almost the entire time. I did play around a bit. As I backed off the pedal I could really see a difference. My filler would not just drop into place. A lot of times it would end up sticking to the tube and I would have to bring the torch over to it and melt it to free it up then go back to my last bead and kind of start over. Maybe I wasn't sticking the filler into the arc far enough or fast enough? I was using 1/16" filler rod.

This is how I prepped the electrode. I use a dedicated grinder to sharpen them, holding them parallel to the wheel. It's kind of hard to see, but it's ground down to a pretty sharp point.

This is the position I was welding in. I would start at the top and pull the torch towards me. I would bring the filler in from the bottom of the picture and most of the time it was leaning up against the square tube to help keep it from bouncing around.

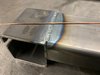

This is how most of the welds turned out. I made a total of 20 of these passes. It's got to be way too hot. Maybe it's just that I had to go slow because of the large gap between the flat surface of the rec tube and the round corner of the square tube. It was a pretty large gap to fill. The top of the weld is undercutting and the HAZ is pretty large.

This picture shows how I was close to burning through, although I never did. The stakes ended up warping quite a bit (not a big deal on this project) right at this strap pocket. From here to the end of the stake is 24 inches. The end of the stakes would be about 1/2" in the air.

This picture shows what my electrode looked like after 7 passes, or about 21 inches of welding. I assume this is normal wear? I could really start to see how my arc went from a very narrow line and ended up as a wide arc, like an umbrella. After sharpening it again it went back to a narrow line again and I could be very precise with where I created a bead.

I found welding these lines to be the easiest ones as the filler just kind of dropped into the gap and filled nicely.

One thing to note is how much filler I used. In a total of 60 inches I used 3 1/2 rods. Does that sound about right?

I needed to build 10 stakes and switched over to MIG after the first 5 were done with TIG. You can see how uniform the welds are. Overall I was pleased with the outcome. I just need figure out if the welding could have been done colder with less/no warping.

The bottom 5 are the ones I did with the MIG welder. I really flew through them. Much smaller HAZ and no warping.

Overall I really enjoyed this project. My end game is to get proficient at TIG welding aluminum. I have done it a couple times and accomplished what needed to be done, but I know it could have been done better. I'm going to try to TIG steel more often so that I can develop all the hand/foot/eye coordination more. One thing I really tried to do this time was moving the filler rod through my hand instead of just moving my hand closer to the work as I used it up. It's hard to do!

In this project I needed to make some trailer stakes with some strap pockets welded to them. The material I used was 3x1.5x1/8" rectangular tube as well as 2.5" square 1/8" tube.

Getting my parts lined up.

These are settings I went with. The 151 seems very high to me, but maybe not. I did have my foot to the floor almost the entire time. I did play around a bit. As I backed off the pedal I could really see a difference. My filler would not just drop into place. A lot of times it would end up sticking to the tube and I would have to bring the torch over to it and melt it to free it up then go back to my last bead and kind of start over. Maybe I wasn't sticking the filler into the arc far enough or fast enough? I was using 1/16" filler rod.

This is how I prepped the electrode. I use a dedicated grinder to sharpen them, holding them parallel to the wheel. It's kind of hard to see, but it's ground down to a pretty sharp point.

This is the position I was welding in. I would start at the top and pull the torch towards me. I would bring the filler in from the bottom of the picture and most of the time it was leaning up against the square tube to help keep it from bouncing around.

This is how most of the welds turned out. I made a total of 20 of these passes. It's got to be way too hot. Maybe it's just that I had to go slow because of the large gap between the flat surface of the rec tube and the round corner of the square tube. It was a pretty large gap to fill. The top of the weld is undercutting and the HAZ is pretty large.

This picture shows how I was close to burning through, although I never did. The stakes ended up warping quite a bit (not a big deal on this project) right at this strap pocket. From here to the end of the stake is 24 inches. The end of the stakes would be about 1/2" in the air.

This picture shows what my electrode looked like after 7 passes, or about 21 inches of welding. I assume this is normal wear? I could really start to see how my arc went from a very narrow line and ended up as a wide arc, like an umbrella. After sharpening it again it went back to a narrow line again and I could be very precise with where I created a bead.

I found welding these lines to be the easiest ones as the filler just kind of dropped into the gap and filled nicely.

One thing to note is how much filler I used. In a total of 60 inches I used 3 1/2 rods. Does that sound about right?

I needed to build 10 stakes and switched over to MIG after the first 5 were done with TIG. You can see how uniform the welds are. Overall I was pleased with the outcome. I just need figure out if the welding could have been done colder with less/no warping.

The bottom 5 are the ones I did with the MIG welder. I really flew through them. Much smaller HAZ and no warping.

Overall I really enjoyed this project. My end game is to get proficient at TIG welding aluminum. I have done it a couple times and accomplished what needed to be done, but I know it could have been done better. I'm going to try to TIG steel more often so that I can develop all the hand/foot/eye coordination more. One thing I really tried to do this time was moving the filler rod through my hand instead of just moving my hand closer to the work as I used it up. It's hard to do!