anderson750

I'm working on it Rose

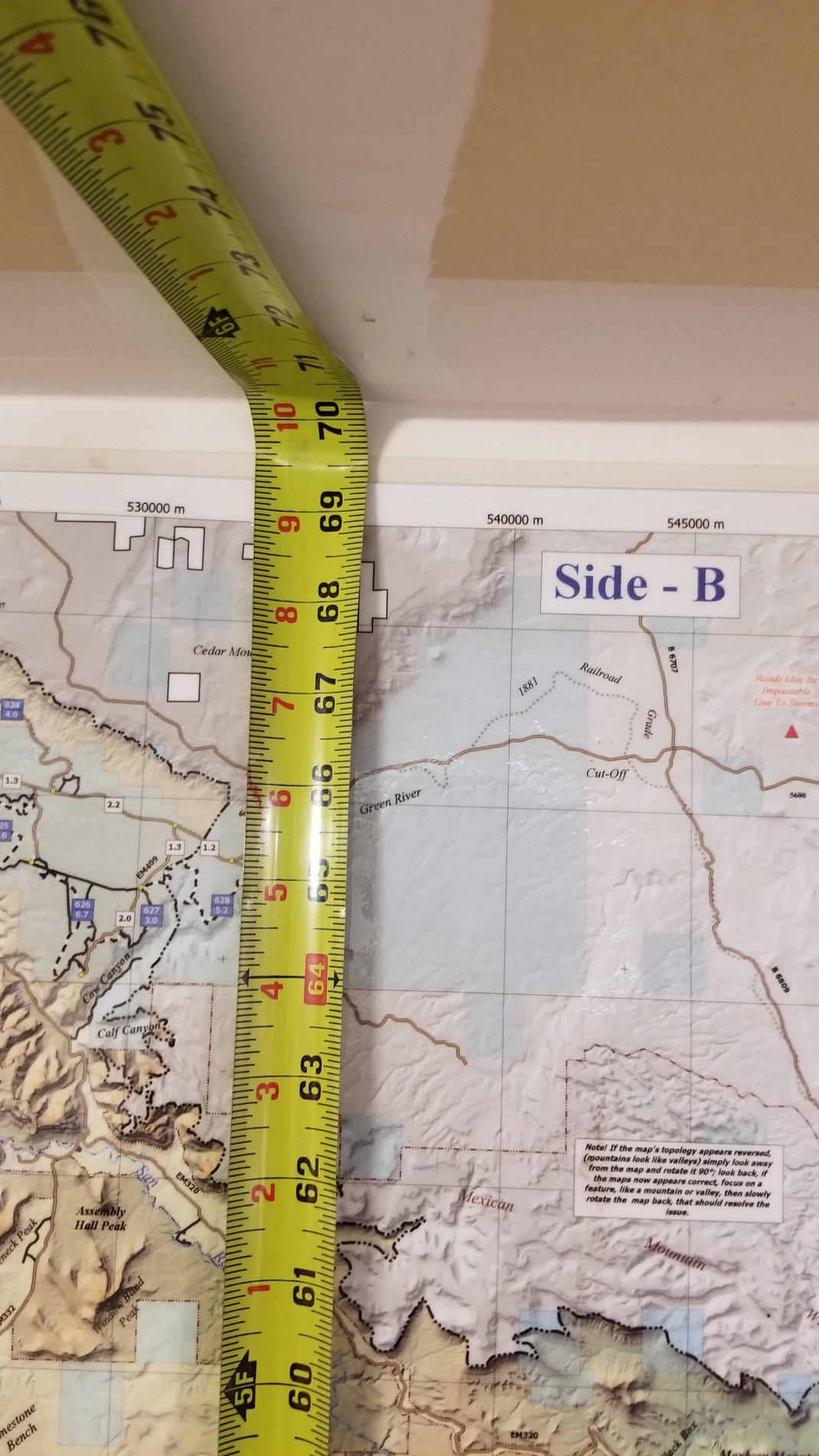

- Location

- Price, Utah

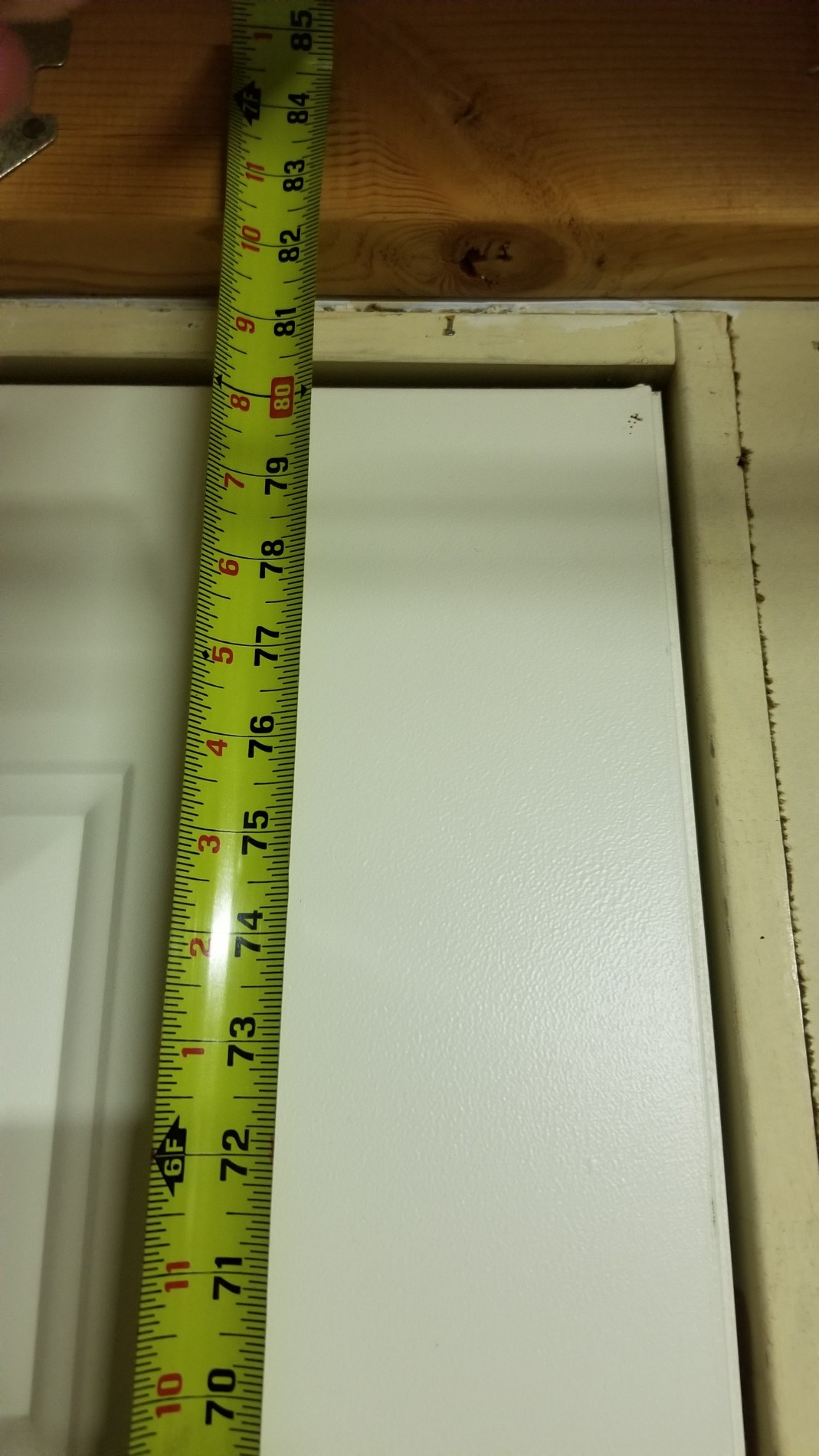

Total ceiling height in my garage is around 14'. On the ground level the 2x10's sit just above the entry door.@anderson750 What is the height of your mezzanine? I have one built and I would love to build a ramp. I can't stand up straight on mine but I would love to do this. Pictures???

Up in the loft it is just a little shy of 6'.......not a problem for me.

Ramp is steep and can be a little tricky with shoes that do not grip the expanded metal.

Total square footage is a little under 300.

Last edited: