You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DANA 80 front axle build

- Thread starter SWALLDOG

- Start date

- Location

- West Jordan

Holy shiz son! How thick is that flange?

I'm assuming you welded the flange on both sides? It looks like a very cool project so far!

I'm assuming you welded the flange on both sides? It looks like a very cool project so far!

- Location

- Grantsville, Utah

Grrr. Want. I have a 2009 Dodge Cummins and I already want to rip off the C's and return to real hubs.

Is there an ABS sensor/tone ring on your original axle? Im not sure how to overcome that issue yet.

Is there an ABS sensor/tone ring on your original axle? Im not sure how to overcome that issue yet.

Tacoma

Et incurventur ante non

- Location

- far enough away

UPDATES!!!

I see you watching!!

I see you watching!!

Holy shiz son! How thick is that flange?

I'm assuming you welded the flange on both sides? It looks like a very cool project so far!

1.5" if i remember right. there is a shoulder that is was pressed up to on the front side. i did three passes on the back side and then one little pass on the front side with the tig. ones the flange is all machined it wont be that thick. i machined down a little step on the front that the rotor sits on. i did want it as thick as i could so there was more surface area to hold the flange on.

That is crazy awesome. Waiting for more!

thanks man :greg:

Grrr. Want. I have a 2009 Dodge Cummins and I already want to rip off the C's and return to real hubs.

Is there an ABS sensor/tone ring on your original axle? Im not sure how to overcome that issue yet.

yes there is. i have a plan for that but have not taken action yet.

UPDATES!!!

I see you watching!!

haha, i'm working on it. stop yelling at me. i just uploaded 38 more pics to my photo bucket so i can post them. what i really need to do is man up and pay so i can just upload them from RME.

ok so here are the hubs after i got them all machined. the one other thing i did machine after i took this pic is machined a little shoulder on the back, right on the outside where the seal goes, so i could press a tone ring on there for my abs. i just need to machine the tone ring and make a mount for the sensor.

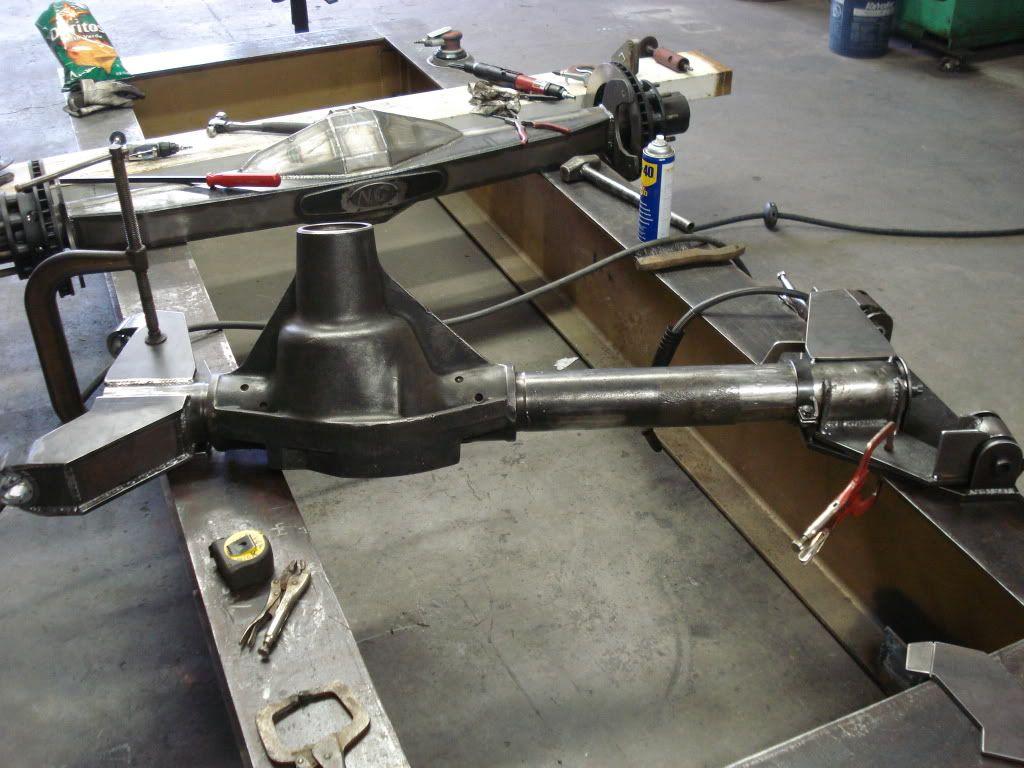

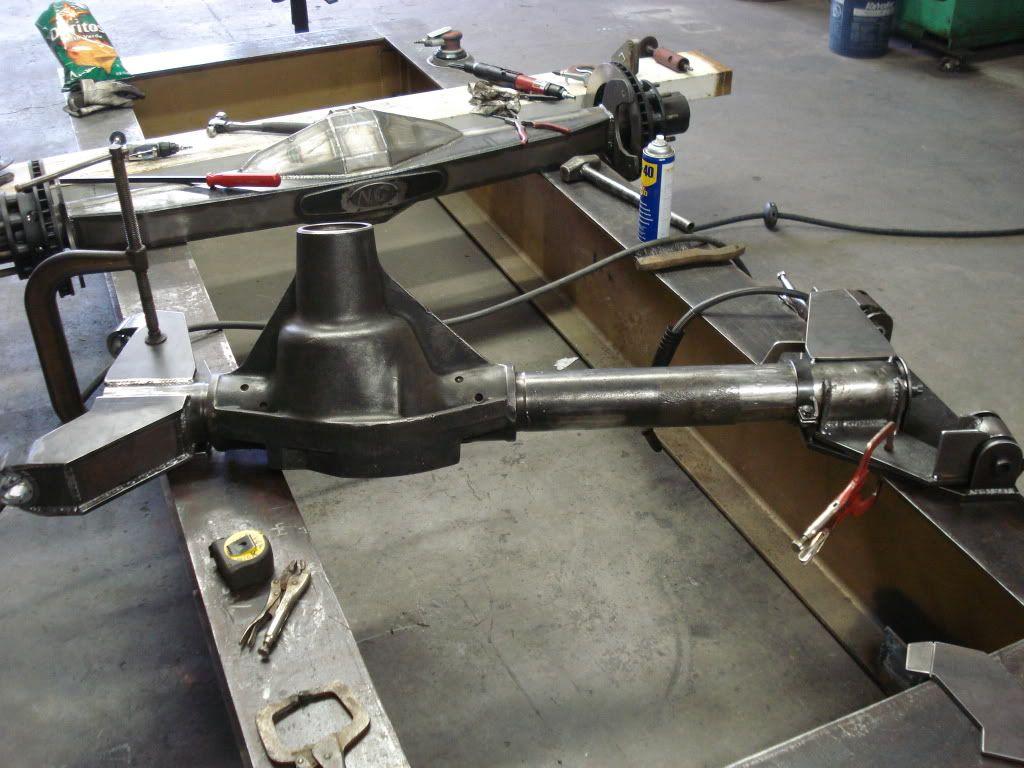

so here are what the inner C's look like. the first pic is the first one that i made with a Dedenbear dana 60 inner C sitting on top of it. the first C that i made i welded it all to a piece of tube and then i was going to press that on to the axle. well i never really liked that idea, so when i came down to it i changed my jig so i could bolt the jig to the axle and weld the C's together right on the axle tube. it worked out a lot better that way. the last pic is with both C's welded together on the axle.

these are pics of the knuckles. the main mounting flange is 1/2". most of the brackets are 1/4" with weld washers, and some 3/8" brackets. the mounting brackets for the brake caliper brackets are 5/8" with a 1/4" weld washer. that way when they were all welded up and machined down the thickness was the same as the stock brackets 3/4".

this is the knuckle with some of the braces welded in and with the start of the arms for the tie rod. i just had them tacked on at first so i could check clearances. i was also checking to make sure that the caliper mounting bracket would fit before i made the mounts for that. i wanted to make sure it cleared the knuckles and the inner C's at full turn. i also wanted to check the tie rod clearance at full turn.

i bolted the wheels up to make sure that everything clears. i had loads of room. i am planing on changing the back spacing of my wheels so they dont stick out so far. i want to take them back about 2.5" - 3" so i turned the wheels around just to see how they would clear if they had about twice as much back spacing was i wanted to move them. the knuckles stuff pretty well in those 22.5" wheels :greg:

this is the track bar bracket on the passenger side. its not done yet, i still need to make a bracket for the outside so it is a double shear. on the inside edge of the bracket a machined a slot so you can get a wrench in there and hold the nut or bolt head, depending on which way the bolt is. its hard to get a socket on it from the back side when all the control arms are bolted on and stuff. the last pic is just a pic from the back will almost all the brackets welded on. getting close to install time.

why i was building a new front end, putting air springs on it i also wanted to build longer control arms. so i build fab lower control arms that were about twice as long as the after market control arms that i have. i made these lower control arm mounts that i could just weld on the frame.

these are the lower control arms that i built. i use a weld on joint on the one end and a 1 1/2" threaded shank joint on the other end. i made my own pinch bolt joints for the threaded end instead of using a jam nut. i have never had really good luck with jam nuts, it seems like on my buggy i am always tightening them before a trip. i like the idea of a pinch bolt so i thought i would try it out, plus you have that many more threads in the link, not taken up by the jam nut.

so the air springs i am running are a firestone spring. they are just about the same diameter as my stock coils. i mounted them in the stock coil buckets which seamed to work out pretty well. i just had to make an adapter to bolt them in. kelderman does this same thing on some of there kits but i have never liked there adapters. they use pieces of strap and it kinda looks weak. i made mine out of a full piece of tube. i wanted to make them as short as possible but still have enough room for the air lines and stuff. they ended up working out pretty slick.