STAG

On my grind

- Location

- Pleasant Grove

So this trailer I bought a little over a year ago, in Pennsylvania, is finally getting the treatment that I had originally intended for it; RV camper conversion.

I originally planned on getting started on this while I was living in Connecticut, but with the exception of some parts accumulation, I never really did get around to any of the build while I was there.

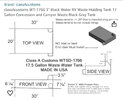

Here’s some pics again from when I first picked it up from the trailer dealer. It’s a 7’x16’ plus a 2’ V-nose, so 18’ length in the center. Admittedly, with what I had/have planned for it, I probably should have went a little bigger. I went 7’ because I figured it would be easier for the Gladiator’s mirrors to see around the sides of it. And went 16’ as I felt that’s the max that I really wanted to pull with the Gladiator.

The Gladiator did tow it fine, with all my belongings in it, from Connecticut to Florida, and Florida to Utah, however I’m sure the H2 will do better at towing it than the Gladiator did. Especially when it’s all finally built out.

I originally planned on getting started on this while I was living in Connecticut, but with the exception of some parts accumulation, I never really did get around to any of the build while I was there.

Here’s some pics again from when I first picked it up from the trailer dealer. It’s a 7’x16’ plus a 2’ V-nose, so 18’ length in the center. Admittedly, with what I had/have planned for it, I probably should have went a little bigger. I went 7’ because I figured it would be easier for the Gladiator’s mirrors to see around the sides of it. And went 16’ as I felt that’s the max that I really wanted to pull with the Gladiator.

The Gladiator did tow it fine, with all my belongings in it, from Connecticut to Florida, and Florida to Utah, however I’m sure the H2 will do better at towing it than the Gladiator did. Especially when it’s all finally built out.