UNSTUCK

But stuck more often.

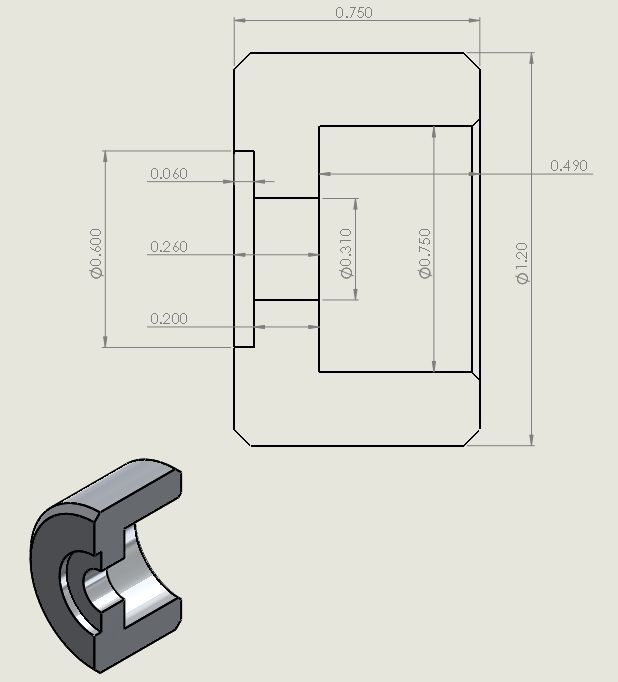

Mike, I was expecting magic when it came time to cut the keyway. As with all magic tricks, once the secret is out, the trick isn't nearly as impressive. I would have snapped pictures with the assembly spinning 1000 rpm's and showed the tool steel in the chuck. You would have really blown our minds then.