idahoyj

Well-Known Member

- Location

- Twin Falls Idaho

Ya, I really need to get the axles geared. It would be SO much easier to drive. Even with 4:1 Tcase, I was pretty hard on the clutch in the rocks.awesome looking rig. Low gears will make it amazing.

I will be sending you guys a PM for Dana 60 and 14 Bolt install kits etc as soon as I get a couple of my extra Jeep parts sold.

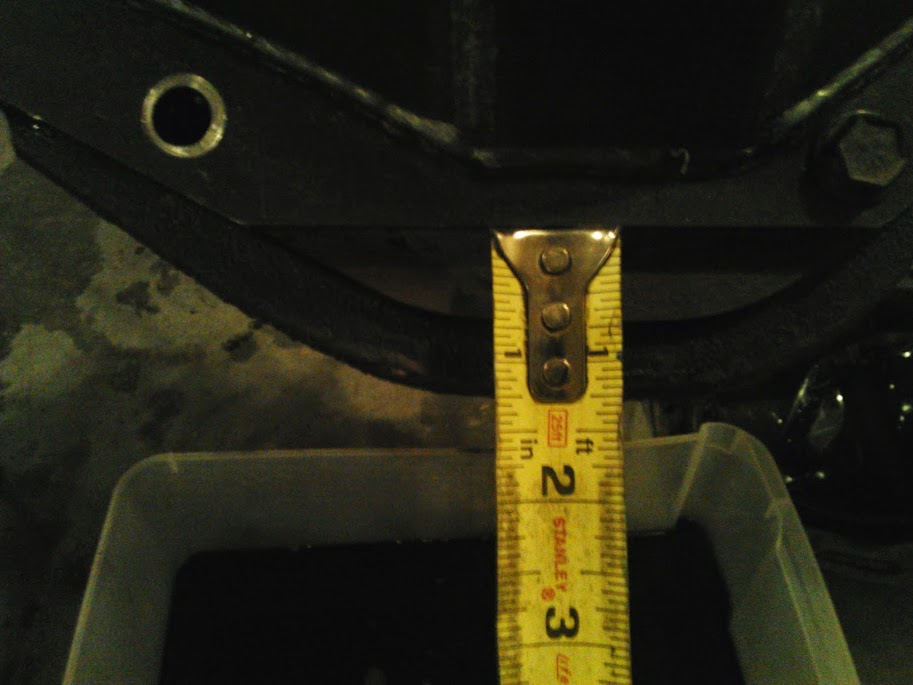

Thats exactly the type that I am looking at. I thought $150 + $15 freight was expensive, until I looked into just buying a 4'x4' sheet of 1/4" for $100 +/- and then having to do all of the drilling and bending on top of that. I will still need to build a cross member to support the trans/tcase so it doesnt rely on the skid plate. I hate supporting all of that stuff every time I take the skid plate off to work on something. I will likely just go with the Barnes unit.Barnes 4wd has some nice skid plates for reasonable prices. I was able to get their flat one and with a clocking ring tuck my Tcase up without a body lift.