Well I've got er running on 2-3 psi. :greg:

I had the wastegate initially modded to 5-6 psi. I added a spring on the actuator rod that opposes the internal spring thus reducing the amount of boost needed to move the rod. The downside is that you lose some travel, but it got the boost down to 2-3psi so it worked out well. I can just thread in the rod end a few turns to increase the boost up to ~7psi (or more by reducing the spring preload).

Boost started building very seamlessly off idle at 1500rpm, and was 3psi by 2000rpm, and will probably be at a full 7psi by round 3000rpm I'm guessing. This is about perfect since I only ever rev the motor to 4500rpm since it hates revving.

I'm getting my MSD BTM ignition box from a buddy soon which will pull timing with boost, then I'll just need an FMU for fueling. I'm also going to put a temp gauge in the intake pipe and see what the IAT's are and decide if methanol/water injection is worth it.

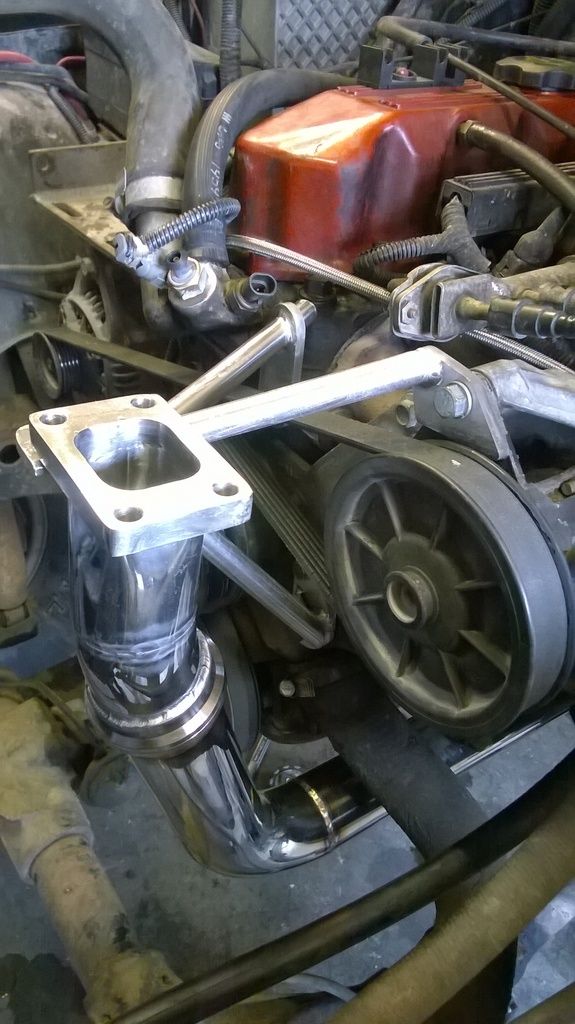

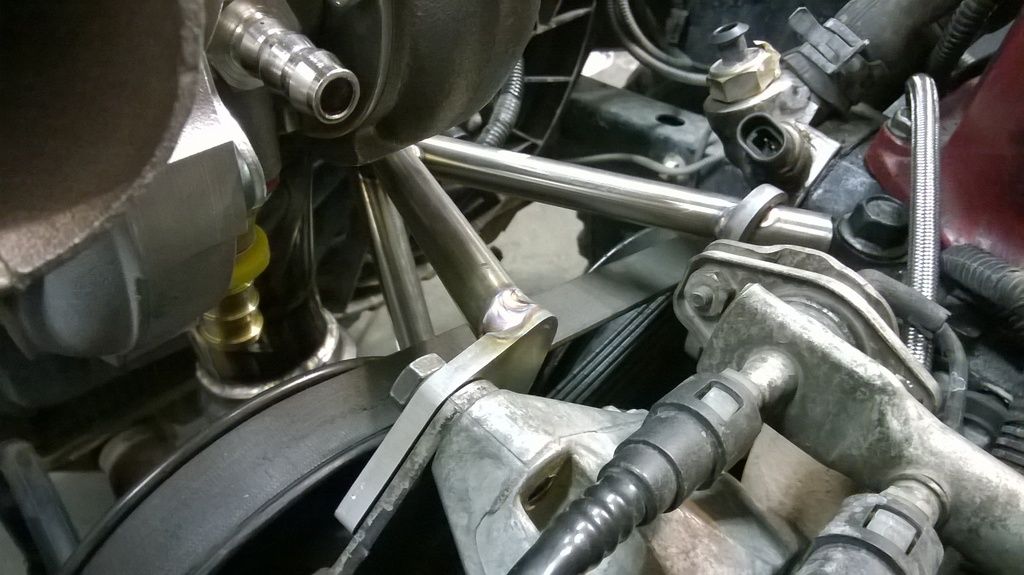

Had to get a little creative to make the turbo oil drain work well enough for a Jeep that see's extreme tilt angles, since the exhaust pipe was blocking access to the oilpan.

Water cooling lines hooked up too.