I've been working on the front frame rails and cross member/bumper for way too long. I really wish I had just left them alone and spent my time installing the engine/trans etc.....

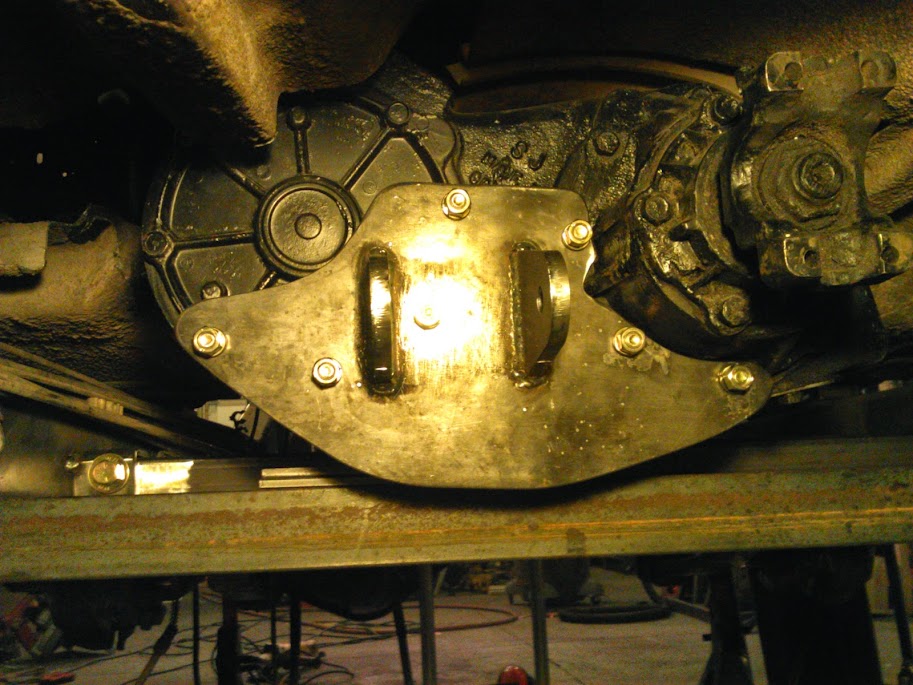

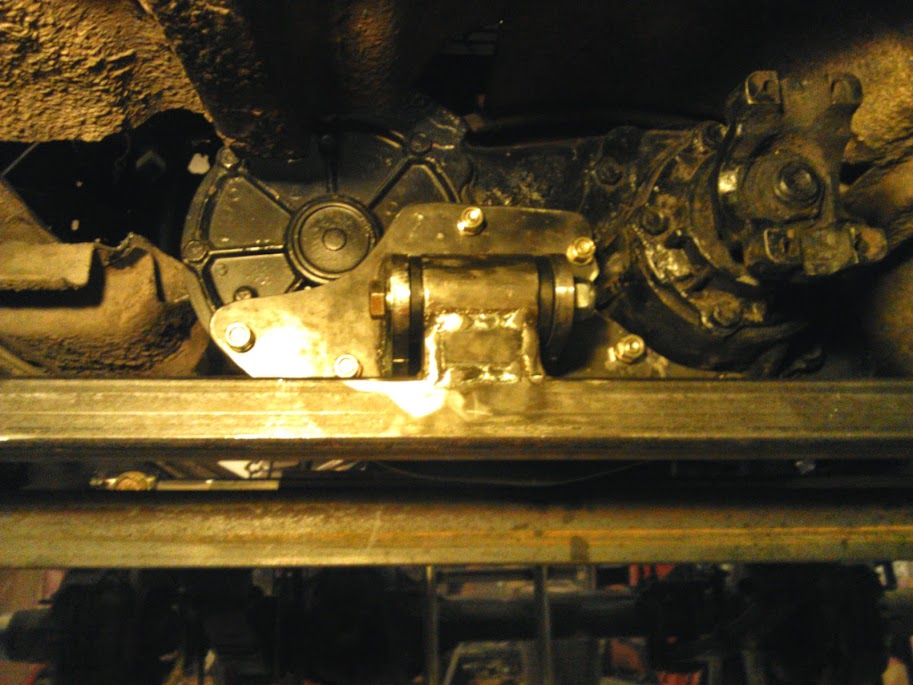

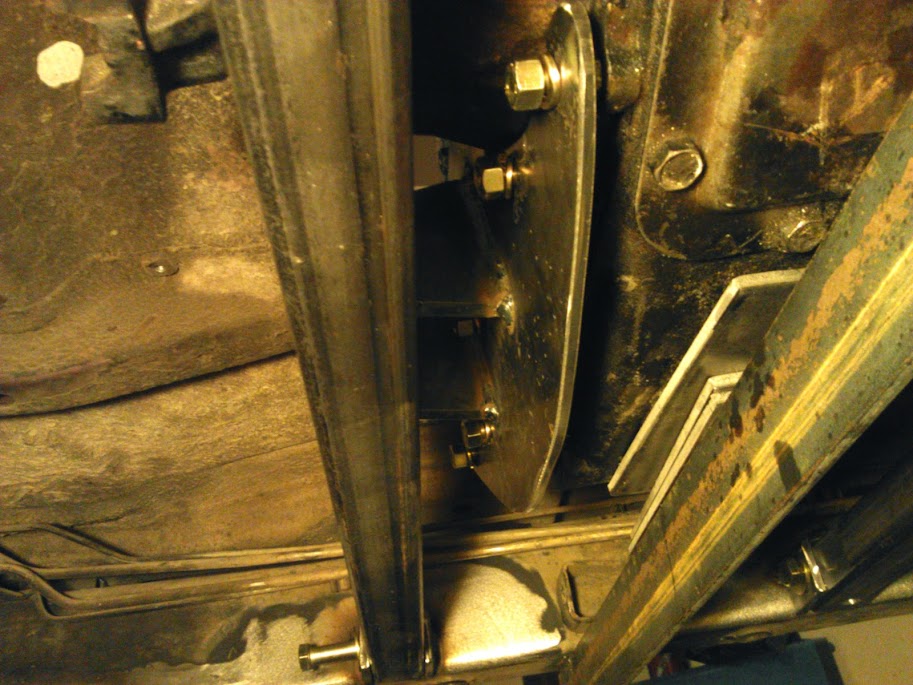

Pics of frame rail progress, ignore my mediocre welding ability.

I found a deal on an NP205 Ford tcase with TH350 adapter on KSL and convinced @JINX to drag it up to Idaho for me. I really want to run the Behemoth Strong Box, and I even bought an NP241 donor case. Unfortunately, I don't see the extra $700 coming my way soon enough to go that route now. I may still go that way some day though.

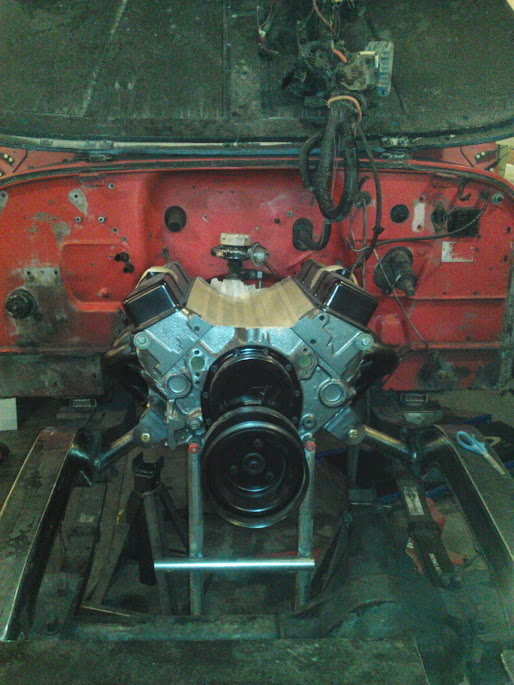

Pics of engine/trans/tcase bolted together.

I also purchased a Griffin radiator from Summit. Hope I can figure out how to mount it!